| Sign In | Join Free | My chinaqualitycrafts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinaqualitycrafts.com |

|

Brand Name : JAGUAR

Model Number : A6

Certification : CE

Place of Origin : Shenzhen, Guangdong, China

MOQ : 1set

Price : To be negotiate

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 30 sets per month

Delivery Time : 10-15 Working Days

Packaging Details : Stand Export Package by Vacuum and Plywood Case

Name 1 : Reflow Furnace

Name 2 : SMT Soldering Machine

Name 3 : SMT Welding Machine

Name 4 : Lead-free Reflow Solder

No. of Heating Zone : Up 6 Bottom 6

Length of Heating Zone : 2400mm

Heating Mode : Up Hot Air Bottom IR

Cooling Mode : Forced Cooling Air

Mesh Width : 400mm

Conveyor Speed : 0-1000mm/min

Power Supply : 380V(Optional 220V)

Startup Power : 16KW

Normal Power Consumption : 3-5KW

Warming Time : 20min

JAGUAR 6 Zones Lead-free Reflow Oven Model No.: A6

JAGUAR A6 Lead-free Reflow Oven was designed for single side mounted PCB, which standard equipe mesh conveyor, standard conveyor width is 400mm, can optional broaden mesh width to meet customer's high capacity demand, conveyor speed is 0-1000mm/min with inverter control adjustment. Up 6 hot air and bottom 6 IR heating zone, temperature up to 300℃, and temperature control precision ±2℃, but it's startup power only 16KW, and normal power consumption is approximately to 3-5KW, it is a high performance energy saving reflow oven.

Specification:

| Model | JAGUAR A6 | |

|

Heating System | Number of heating zones | Top 6/Bottom6 |

| Heating passage | 2400MM | |

| Heating style | Top: hot air; bottom: IR(top and bottom hot air is optional) | |

| Cooling style | Force air | |

|

Conveyor System | Max. Width of PCB | 350mm |

| Mesh belt width | 400mm | |

| Conveyor Direction | L→R(or R→L) | |

| Process Height | 880±20mm | |

| Conveyor type | Mesh(Mesh+Rail is optional) | |

| Conveyor speed | 0-1000mm/min | |

| Fixed track | Front track fixed(option: rear track fixed) | |

|

Control system | Power supply | 5 line 3 phase 380V 50/60Hz |

| Total power consumption | 20kw | |

| Startup power consumption | 16kw | |

| Steady consumption | 3-5KW | |

| Ramp Up time | About 20 mins | |

| Temp. setpoint | Room temperature-300℃ | |

| Temp. control method | PID close loop control & SSR driving(PLC+PC is optional) | |

| Temp. control precision | ±2℃ | |

| Data storage | Process Data and status storage (80 GB)(machine with PC) | |

| Nozzle plate | Aluminum Alloy Plate | |

| Abnormal Alarm | Abnormal temp. (overtemp/low temp.) | |

| Board dropped alarm | Tower light: Amber-warning, Green-normal, Red-abnormal | |

|

General | Dimension(L*W*H) | 3500×800×1320mm |

| Weight | 600KG | |

| Color | Computer grey | |

Features:

No.1 The unique advanced long life heating system

1.The heating system adopt the Swedish nickel heater with efficiency and energy-saving. The

peak wave length of the radiation power is 4UM with curved surface reflector increasing temperature ramp up speed, improve the thermal efficiency. The special forced-air circulation system make PCB and the component heated uniform and eliminate the "shadow effect" completely.

2. Using special high temperature barrier structure for heat preservation and special iron in

Heating passage.

3. Using imported Taiwan SanYue long shaft high temperature blower motor and W shaped heat duct, no noise & vibration, convenient for maintenance.

4. Heating zones with porous aluminum plate directing the hot air to guarantee the heat evenly distributed to the PCB. Hood can open completely so that convenient for cleanup.

No.2 Smooth and reliable transmission system

1. The conveyor system use STK adjustable speed motor imported from Taiwan matched with the 1:150 turbine reducer can running smooth, speed varies in 0-1000mm/min.

2. Independent roller structure support and match stainless steel mesh belt to make the running smoothly and the speed precision is up to ±20 mm/min.

3.Special stainless steel mesh belt: durable and wear-resistant, long lifetime.

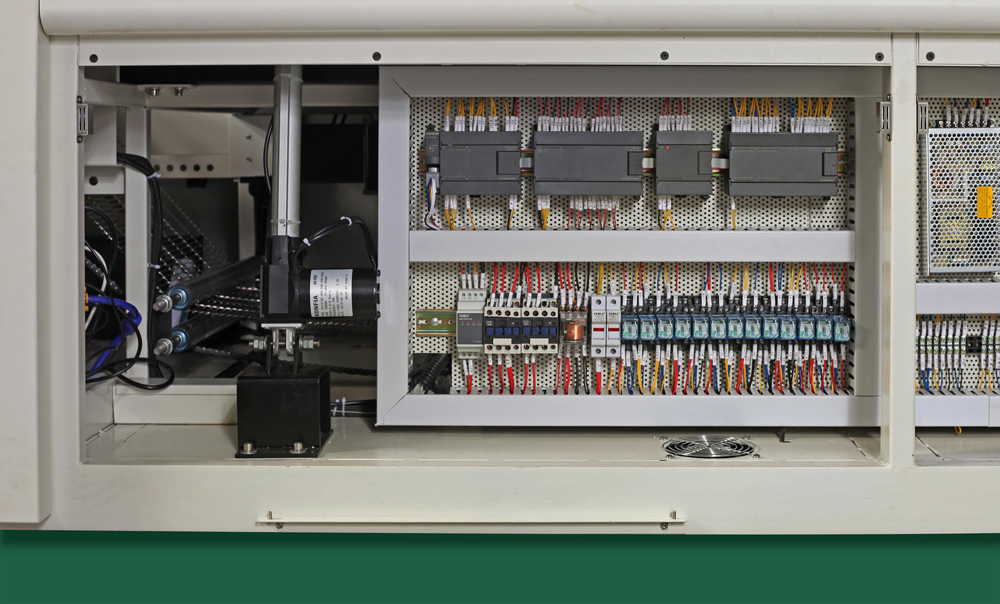

No.3 Stable and reliable electrical control system

1. It adopts imported thermostat control which owns fuzzy logic and PID close loop system. It can fast response to temperature changes and ensure temperature compensation by PID intelligent operation.

2. Using thermocouple imported from Taiwan to each temperature zone, it can fast and sensitive response the changes in each temperature zone, feedback and control timely, compensate the temperature stability in each zone.

3. Special SSR solid state relay matched with dedicated heat dissipating block improve the heat efficiency greatly and prolong the lifetime effectively. Non-contact output and fuzzy control function by thermostat, can monitor the changes of environmental temperature, controlling the heating device by minimum pulse, ensuring the high precision of the temperature control & the uniform internal temperature. The length ,direction, temperature distribution, all these meet with IPC standards .

4. Heat energy is abundant, heat up fast, it’s only need 20 minutes from room temperature to set-point temperature.

5. Failure diagnosis, visual & audio alarm.

6. Delay shutdown production function, uniform cooling after the shutdown: prevent hardwares thermal damaged.

Please contact me if you have in inquiry!

Thanks & Best Regards,

Nona Xiao

Jaguar Automation

14th Building,Furong Industrial Zone,Xinqiao Street, Shajing, Bao'an District, Shenzhen,China

Ph: 86-755-23316315

Mob: 86-13590488442

Fax: 86-755-29497125

E-mail: sales04@jaguar-ele.com Web: www.jaguar-ele.net

|

|

IR Reflow Oven SMT Soldering Machine Mesh Conveyor Up 6 Bottom 6 Heating Zone Images |